THE DESIGN

UNIQUE DESIGN

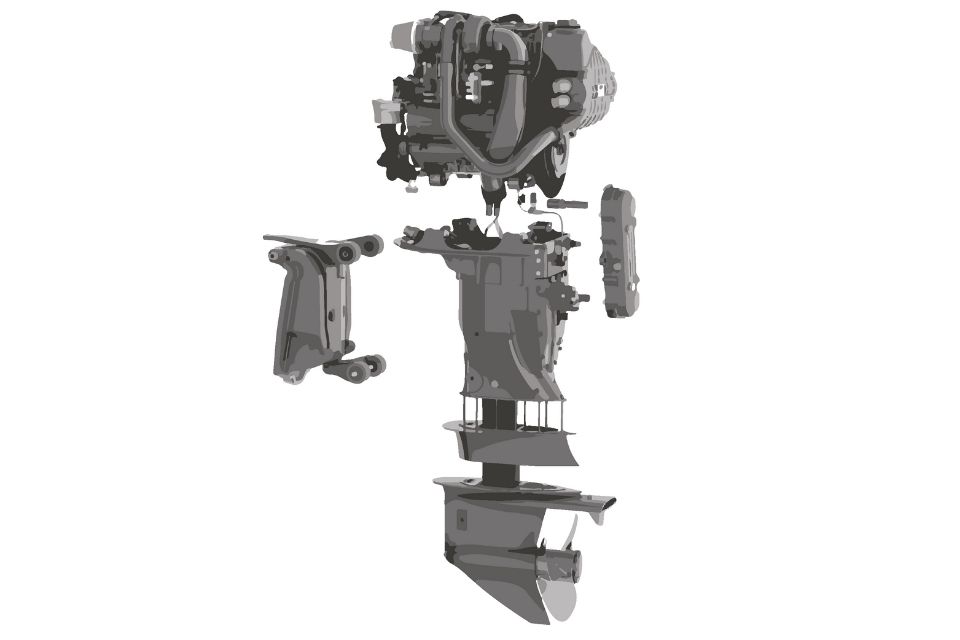

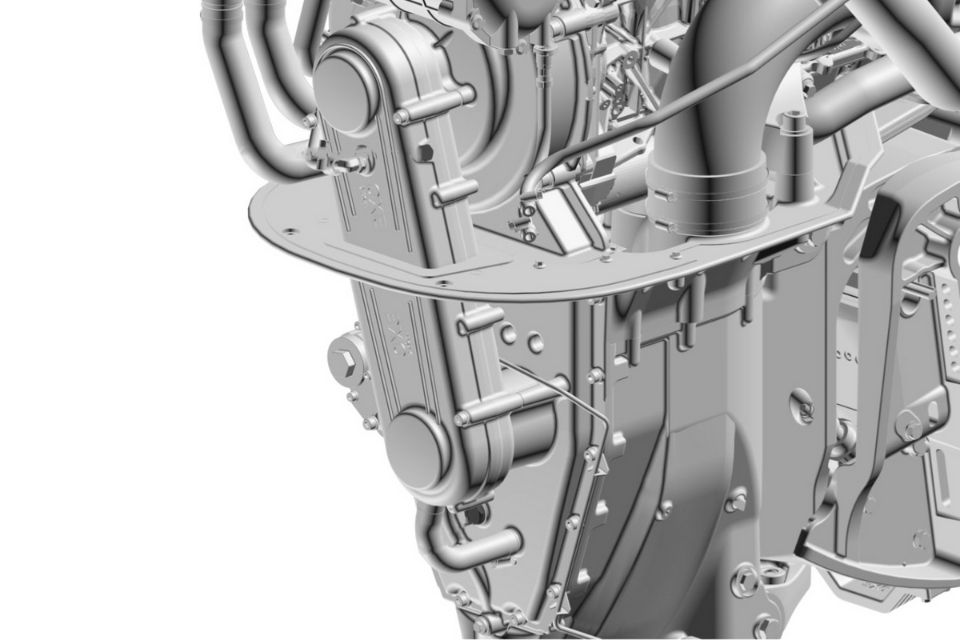

The diesel engine on the OXE Diesel has been adopted from the automotive industry. In relation to a vertically mounted outboard engine, a horizontally mounted engine reduces wear and improves heat dissipation. The power is transferred to the gearbox through the primary belt which can be positioned in either high speed or high torque setting. From the gearbox output a second belt transfers the power directly to the propeller shaft, eliminating the need for a conventional bevel gear system completely.

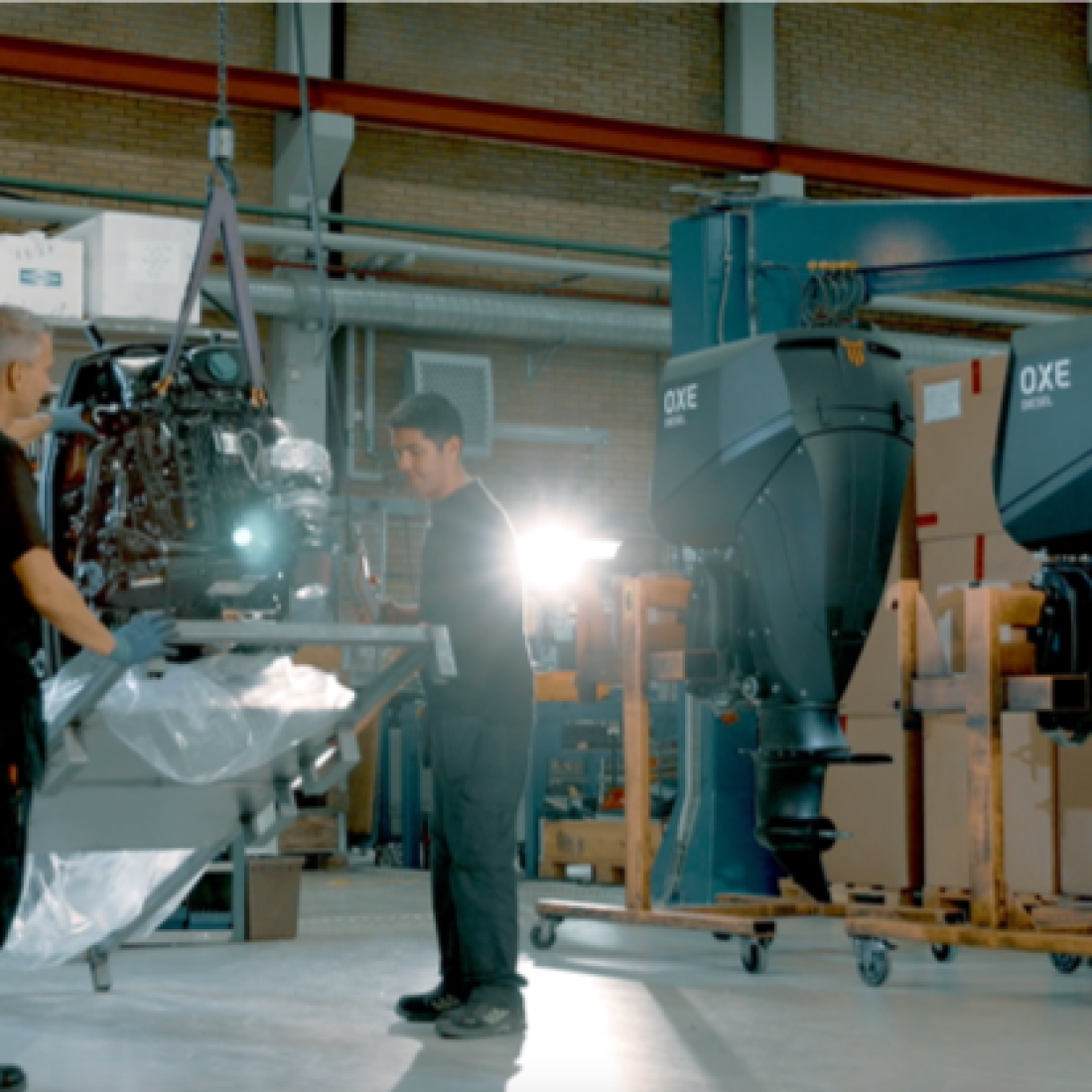

A MODULAR DESIGN

The patented belt technology enabled the team to design a robust outboard unit that effectively, and over a long lifespan, transfers high torque from automotive or industrial engines to the propeller with minimal transfer loss.

The diesel engine is mounted horizontally; the power is then transferred to the gearbox through a primary transmission. From the gearbox output, a belt transfers the power to the propeller shaft.

The engine is mounted on the adapter plate with four robust anti-vibration mountings which allow the unit to endure punishing commercial use and be quickly and easily replaced when time for overhaul. All parts are easy to access and can be replaced without having to disassemble the unit.

THE COWLING

The cowling of the OXE Diesel is developed to reflect the strength of an ox; a clean, strong design with large non-reflective surfaces joined together by clear edges. It is broken up into individual pieces that are all easy to replace without having to replace the whole cowling. The top of the cowling is flat, designed to be used as an extra service surface, or a step for the user when moored, or even a table if needed.

The only organic curve allowed is the shape of the ox-like bend that transcends from the waterline all the way to the top of the engine. The bent neck has a purpose; to be easily removed from the back to allow for easily accessible service points.

The air vents are deliberately placed on the top of the cover to minimize the risk for water intrusion, while the design still allows for external airflow from snorkels. The cowling is deliberately designed without protruding features to minimize risking equipment being caught on the engine. The oversized drains of the OXE Diesel are developed to be capable of draining out more than twice the amount of water that regulations demand.

It all adds up to the fundamental concepts of reliability, power, and control, always with a focus on function before form.

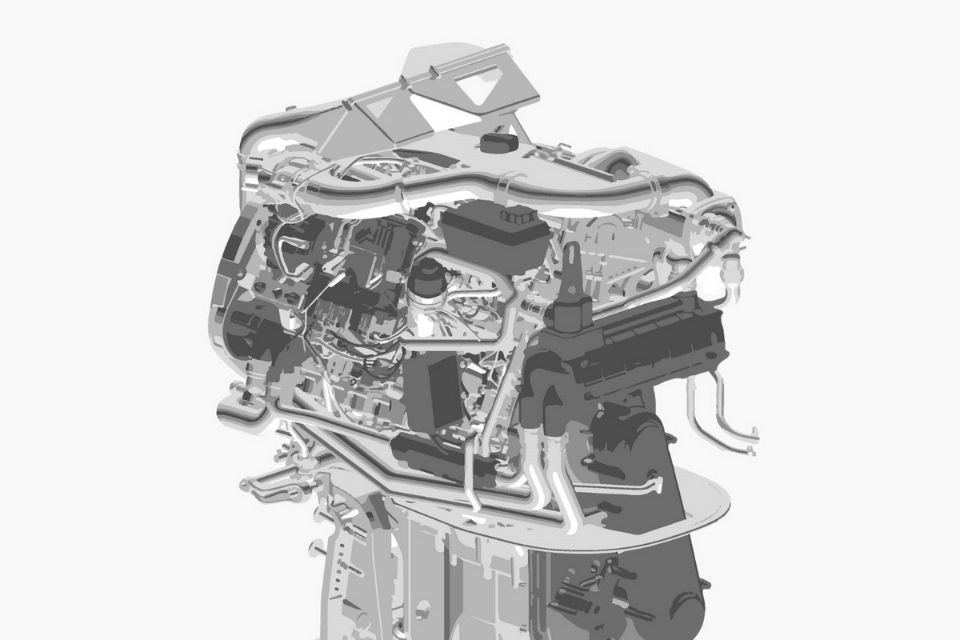

THE POWERHEAD

The powerhead in the OXE Diesel is a proven, robust diesel engine developed by the automotive industry. Inspired by modern inboard technology, the powerhead of the OXE Diesel is mounted horizontally and marinized with a closed-circuit coolant system.

In relation to a vertically mounted outboard engine, a horizontally mounted engine reduces wear and improves heat dissipation. The marinization of the engine include separate systems for seawater, heat exchangers, intercooler and oil cooler. All system functionality ensures that the engine, electrical system, fuel system, and air intake withstand marine conditions.

The horizontal placement of the engine allows for the use of a high output alternator, which is required by power-demanding equipment. It can also run, for example, a cabin heater, which is often requested by users in cold weather operations. The high output alternator (up to 180 amp) enables powering of electrical equipment such as air conditioning, freezing, and fishing equipment. All service access points are positioned toward the deck side of the unit for easy maintenance and service.

THE PRIMARY TRANSMISSION

The use of state-of-the-art diesel engines further escalated the requirements on the power train. The bevel gear systems found in traditional inboard and sterndrive power trains, with vertical shafts and dog-clutches, are neither designed for nor able to cope with, the high torque required or long hours demanded by commercial marine applications.

The primary transmission provides the user of OXE125-200 with the ability to change the gear ratio of the unit to fit various demands and driving styles. Depending on the needs of the operator, high torque or high-speed can be selected for OXE125-200. It’s designed as a separate unit that is easily reversible. By switching the orientation of the primary transmission housing, the user can change the gear ratio between 1.73:1 and 2.17:1. The OXE300 comes with a fixed gear ratio of 1:39:1.

THE GEARBOX

The gearbox is mounted separately, under the powerhead but above the waterline. It is therefore protected from damage if the unit runs aground. The gearbox is a robust electro-hydraulically operated system with two multi-plate clutch packages that allow for high torque and power transfer.

It is designed to withstand crash stops and operates both clockwise and counterclockwise to allow the user to mount or even transfer the OXE Diesel on any boat and between different configurations. Propeller rotation is simply selected from the display settings.

The power is transferred to the gearbox through the primary system. From the gearbox output a poly-chain carbon fiber belt transfers the power directly to the propeller shaft, eliminating the need for a vulnerable and inefficient dog clutch and bevel gear system. The reduced need for equipment to be placed under the waterline also makes it possible for a better, slimmed down and more hydrodynamic design underwater.

OUR BELT TRANSMISSION

The patented primary belt transmission allows full range torque transfer capability without affecting the hydrodynamics of the OXE Diesel. It means that solutions that were previously only available for inboard applications can now be applied to outboard solutions. The introduction of the primary belt transmission also means that the bevel gears found in most leisure products can be completely removed for a more durable and efficient solution. The belt drive allows for increased torque transfer to the propeller, as well as for smaller torpedoes and slimmer submerged modules under the waterline. The result is a design with less drag, which reduces fuel consumption and increases speed in comparison with bevel gear-driven units.

The patented OXE Diesel system has revolutionized the outboard engine market’s dependence on a traditional outboard drive system, eliminating the need for an antiquated, vulnerable and inefficient dog clutch and bevel gear system.